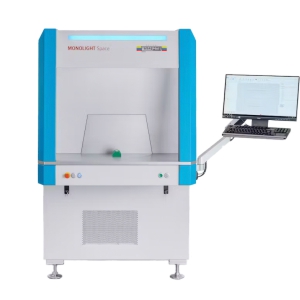

MONOLIGHT Space

The MONOLIGHT Space is the “big brother” of our MONOLIGHT series and offers a wide range of beam source options. Not only fiber lasers, but also CO2, UV and USP fiber lasers with different outputs can be integrated. The optimum beam source is determined individually through application tests. Thanks to our in-house laser application technology, preliminary samples can be requested at any time.

Each MONOLIGHT Space is equipped with an electrically adjustable Z-axis, which is conveniently controlled via the software. Stored parameters enable quick and easy switching between different jobs, making lasering on different levels a piece of cake. The pre-installed TAMPOPRINT Laser Suite software ensures seamless integration and easy operation.

Learn More!MONOLIGHT Compact

With the MONOLIGHT Compact, you will have a powerful tool for making precise and fine marks on smaller components, for labeling or personalizing them. At the same time, it offers you the independence to produce your laser-capable pad printing clichés on your own without having to rely on external service providers.

Depending on your requirements, you can choose between 3 fiber laser powers to achieve the best possible results. The tabletop laser unit is a true multi-talent and opens up new possibilities in laser processing for you. Turn your creative ideas into impressive reality - the tabletop laser unit is your ticket to the world of high-precision laser marking and independent production of pad printing clichés. Discover the versatility and performance of the MONOLIGHT Compact now!

Learn More!MOF-PROMO HP

Procedures for high-precision, rapid inner and outer laser marking of all types of closures for the drinks industry. Large, tamper-proof quantities can be produced. With its short and compact construction, the “MOF-PROMO HP” can easily be integrated into existing production lines for all types of closure caps.

- Lower energy costs

- Reduced repair costs

- Almost maintenance-free

- Improved legibility of the marking

- Reduced space requirement

- Up to 2,400 laser marked parts/min. (depending on product)